AI Pt. 1 - Old MacDonald Has a Bot. EI AI… Oh

Even a cat has things it can do that AI cannot. - Fei-Fei Li, American computer scientist

This article is the first of a three-part series on my perceptions of AI and how it’s changing the world around us. Including the realm of the copywriter. Of course, any good article on artificial intelligence must include the rise of automation as well. In reality, mechanical and computer innovation has been a factor in society for a long time. And much like AI is allegedly disrupting the realm of the word-artisan, mechanization has always been disruptive.

And yet… we survived.

The issues in this series cover:

Early automation and the four stages of the industrial revolution,

The evolution of writing, from cave dwellers to AI-generated text, and.

The missing ingredient of AI copywriting and how you, the human writer can supply it.

At the end, we’ll discuss what this means for professional copywriters. And outline steps to future-proof your writing career.

Let’s begin with mechanization, automation, and technology in manufacturing.

The rise of the machine in manufacturing

According to Bill Gates, founder of Microsoft:

“The first rule of any technology used in a business is that automation applied to an efficient operation will magnify the efficiency. The second is that automation applied to an inefficient operation will magnify the inefficiency.”

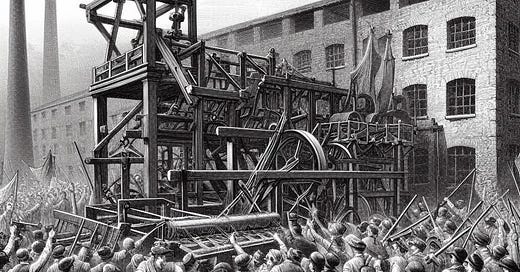

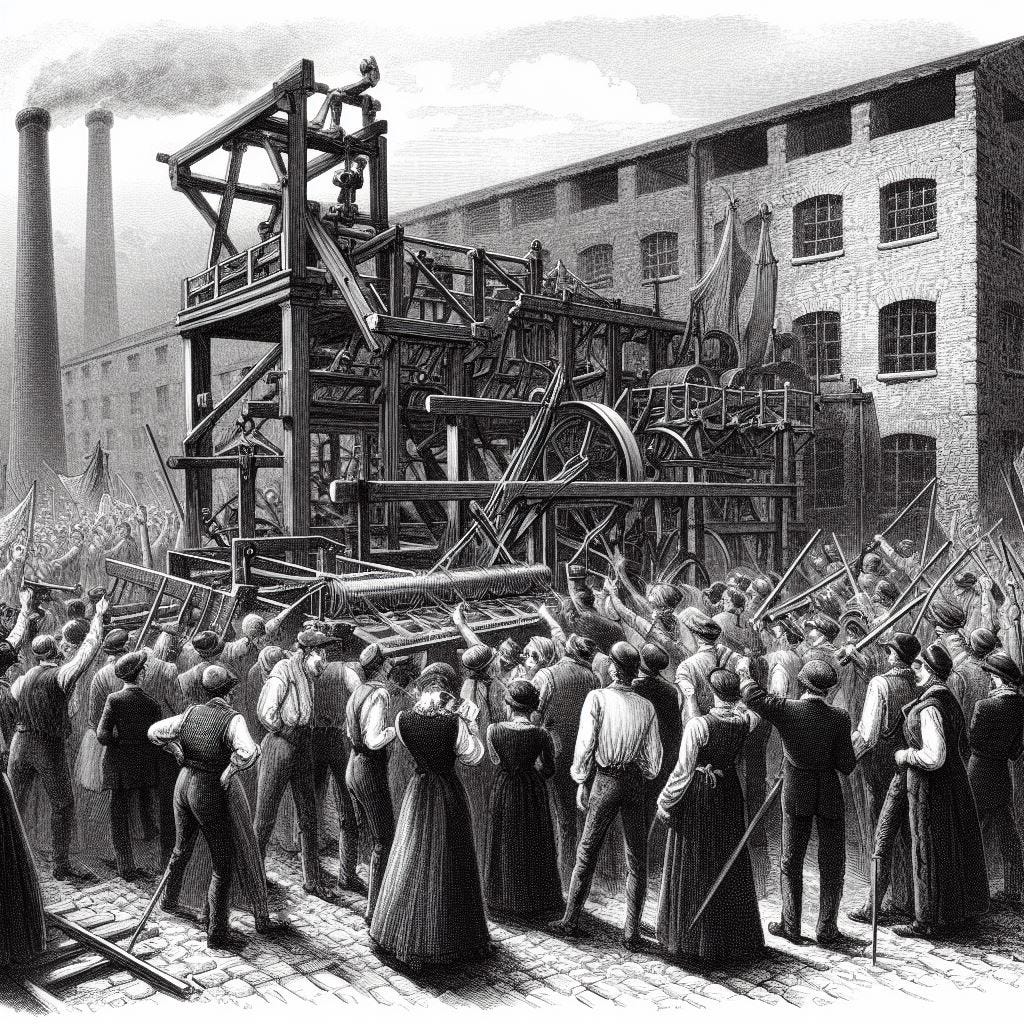

Mechanization stretches far back into the annals of the industrial revolution. And so has resistance to it. In fact, there is a term for those who resisted automation: Luddites.

For the most part, Luddites were skilled craftsmen who protested against the rise of mechanized looms and the unskilled laborers who operated them.

From the History website1:

“Luddite” is now a blanket term used to describe people who dislike new technology, but its origins date back to an early 19th-century labor movement that railed against the ways that mechanized manufacturers and their unskilled laborers undermined the skilled craftsmen of the day.

”

The original Luddites were British weavers and textile workers who objected to the increased use of mechanized looms and knitting frames. Most were trained artisans who had spent years learning their craft, and they feared that unskilled machine operators were robbing them of their livelihood.

Cheaper mass production was one of the driving factors in the industrial revolution.

It still is.

Each industrial age or revolution had a main contributing force or forces. While there is some overlap, there are 4 industrial revolutions. In a nutshell:

The first industrial revolution began in the 18th century, driven by mechanization and steam power. That’s where the original Luddites factor in, rebelling against steam engine powered looms. Of course, the steam locomotive drove transportation to new horizons.

The second age began in the 19th century. The “prime movers” of that revolution were the discovery of electricity and implementation of the now common assembly line. Henry Ford brought assembly line production to the automotive industry. But he copied the idea from a slaughterhouse in Chicago.

The third industrial age—birthed sometime in the ‘70s—was powered by electronics, computers, and robotics. This is where partial automation with little to no human intervention took hold. But humans were still a vital part of most operations particularly in backup, quality control, and mantenance. That’s where my work in the processing plant evolved… partial automation, guided and backed up by human “watchers.”

The current age, the fourth industrial revolution—dubbed Industry 4.0—is likely the fastest expanding evolution of any age preceding it. Building on the 3rd Industrial Revolution’s computer technology, machine networking and edge computing now interface with the so-called Digital Twin that is the Internet or Cloud. Manufacturing facilities around the country, the continent—even around the globe—can communicate with and even be controlled by one remote location.

While we often think of automation in industrial manufacturing, such as automobile or equipment building factories, even Old McDonald uses automation. AI plays a role in processing and distributing our food supply.

From soup… to nuts.

I’m a retired industrial electrician and maintenance mechanic. I worked in a food processing plant Over 36 years, I watched as mechanization, automation, and computer-driven technology assisted, and eventually replaced, several of my coworkers.

Part of my job was to fix broken machines and systems and make them purr again. But sometimes, it was more involved.

A major part of my role for the last 15 years was to install new automation equipment.

A lot of this was to help protect workers’ health and well-being. Machines took on tasks that were repetitive, ergonomically unsound, or downright dangerous.

Of course, there was some opposition to it, mostly from the hourly laborers. Many felt they would eventually be replaced by the machines. For some, that was a correct assumption. While many were shifted to other manual-only positions, not all were so lucky.

A major factor and consideration when purchasing new equipment was—and always will be—the amount of manhours or labor expense it will replace or reduce. Labor costs were always a part of the equation when evaluating a new machine or system.

Machines don’t require benefits and never call in sick. And they don’t gripe about overtime or taking vacations.

How many laborers can we replace with new technology?

That remains a driving line item for purchase, especially in the current age of Industry 4.0 and beyond.

Even out on the farm, mechanization, automation, and computer tech like GPS tractor guidance, automated sorting, and AI-assisted distribution allow one person to do the work of an army of workers.

Old MacDonald’s family farm is most assuredly competing with huge corporate-owned, tech savvy operations.

Old MacDonald must accept and employ technology to not just compete… but to ensure his very existence.

In the modern Industy 4.0 factory, AI is used to make split-second decisions in scenarios where a human couldn’t. Coupled with sensors and actuators, computer programs, powered more and more by AI technology, help control flow and increase productivity.

Like It or like it not… tech-mech is here to stay

The Luddites in the late 1700s couldn’t stop mechanization, even though they tried by destroying mechanized looms. Neo-Luddites who oppose technology are likely in the same boat.

In the shuffling madness

Of the locomotive breath

Runs the all-time loser

Headlong to his death

He feels the piston scraping

Steam breaking on his browOld Charlie stole the handle

And the train it won't stop going

No way to slow down

Oh-ohExcerpt from “Locomotive Breath” by Jethro Tull

Technology is as unstoppable as a smoke-belching freight train as innovations and inventions continue to populate the manufacturing landscape. Artificial Intelligence, more often referred to as AI, pushed automation and mechanization into a new era of precision and control… to varying degrees.

And it will continue to do so, on into the future.

I’m not sure if AI is a good thing or a bad thing. Jury’s still out on that. However, AI does help me keep my RAV4 rolling down the highway between the lines.

ShazBot!

Okay. I know what you’re thinking.

“Steve… what in the world does this have to do with writing in general, and with copywriting specifically?”

Actually, a lot.

And we’ll look at the evolution of writing, from cave art to AI, in the next issue.

Talk soon!

Steve M

Interesting piece of history. So it's true. Us humans are not fond of change. Especially when our jobs/livelihood could be at risk. Easy to see the connection with AI in today's world. Nicely done Steve!

This gonna be a great series.

And when Steve, like tech-mech, gets rolling, there’s no stopping him either.